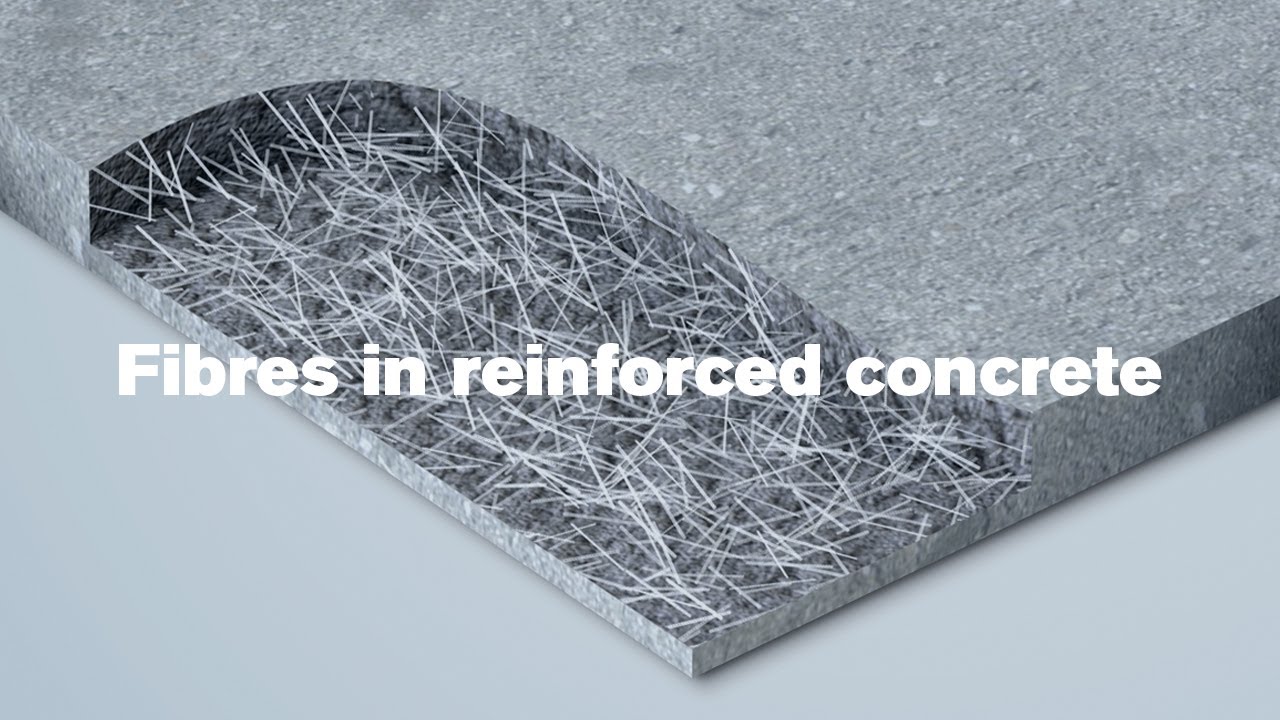

Steel Fiber Reinforced Concrete

- For improving long-term behavior, enhancing strength, toughness, and stress resistance, SFRC is being used in structures such as flooring, housing, precast, bridges, tunneling, heavy duty pavement, and mining. There has been considerable research on the mechanical behavior of SFRC in recent years. The past research results indicate that the SFRC has relatively good properties in comparison with the normal concrete. Therefore, the use of SFRC could be a solution for improving the mechanical performance of the composite steel-concrete beams under negative bending moment.

-

Concrete materials are very brittle when subjected to normal tensile stresses and impact loads. There has always been a

need to add reinforcement to concrete to compensate for this lack of ductility. In many cases, the concrete member is kept

intact using steel bars or welded wire fabric reinforcement in one or two locations of potentially high stress. If the

concrete cracks, the concrete is hinged together at those limited locations.

-

Steel fiber reinforced concrete is able to withstand much greater stresses, both prior to and after cracking.

- Homogeneously reinforced concrete has substantially greater fatigue and impact resistance than conventionally reinforced materials greatly reducing the potential for fractures and spalling. If the concrete cracks, steel fiber reinforcement is able to minimize the crack width.

- Steel fibres, an alternate concrete reinforcing material, are high tensile steel wire with Hooked End, Crimped round and

Crimped Flat steel fiber together for compactness and uniform desperation in concrete. Steel fiber concrete flooring can provide superior resistance to minimize cracks in hardened concrete, as well as maximize it to either withstand heavy loads, dynamic or static. If you decide to use steel fiber concrete flooring you can select to use a joint- less floors that have minimal joints, providing spaces without joint.

Advantages Of Steel Fiber For Concrete Flooring

- An increase in load bearing capacity due to the redistribution of stresses.

- Joint spacings can considerably be increased.

- Reduction of concrete slab thickness.

- Increases durability.

- Low maintenance cost.

- Improved flexural properties.

- Reduced absorption of water, chemicals, etc.

- Faster construction due to eliminations of rebar reinforcement.

- Easier positioningof joints.

- Reduces site labor for managing steel reinforcement.

Our Elite Clients

We Serve Clients Nationwide